by Max Mundt, VP Business Development at Insempra

The level of cutting-edge innovation in bio-manufacturing is astounding. Unfortunately, most innovators never see their ideas become products due to a lack of resources (time and/or money) and expertise (mainly upscaling and commercialization). As a former scientist and previous biotech founder, I know the struggle. As VP of Business Development at Insempra, my team and I can help innovators grow. We discover the hidden gems, find ways to collaborate, provide what is necessary and generate a win-win-win situation – for us, our partners and the planet.

Finding partners that are a good fit for Insempra’s model means analyzing loads of academic institutions, SMEs, start-ups and innovative business units at corporations.

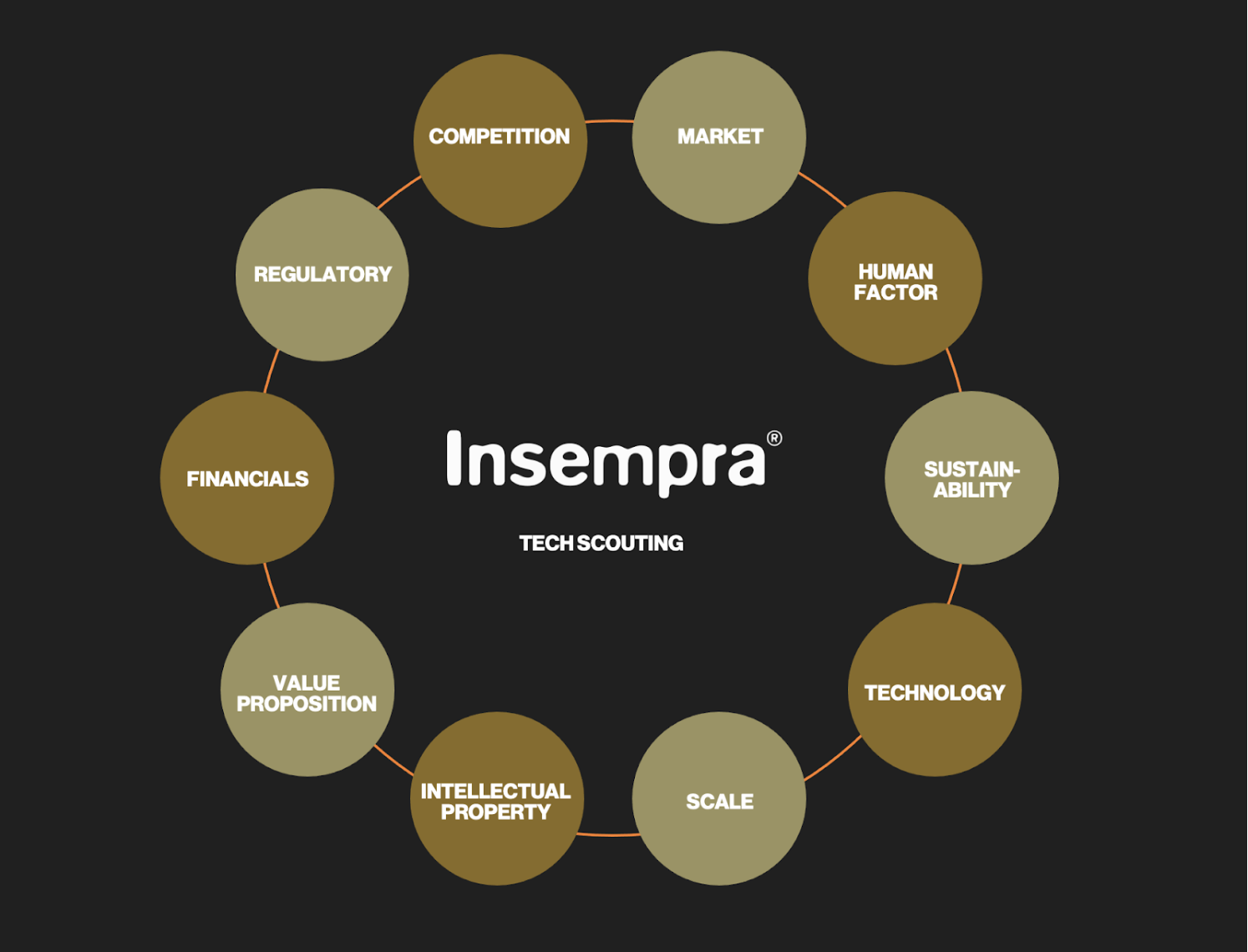

We have created a framework of 10 criteria to evaluate new technologies in order to make faster decisions. We use this framework while looking for new potential partners and collaborators during our tech scouting process.

1. MARKET

The most significant filter is the market. Products that we (co)develop with partners must fit within the Insempra target markets of cosmetics, food, and fibers. Of course, market size is an important factor, as is the question of whether the products will be novel or drop-in replacements.

2. ‘THE HUMAN FACTOR’

We like people that we simply click with. The human factor determines whether possible partners share our vision of the regenerative revolution in addition to being outstanding at what they do and how they do it. We really value rapid communication and decision making.

3. SUSTAINABILITY

This may seem obvious, but I believe that the concept of sustainability is frequently oversimplified. Of course, we appreciate any solution that has a lower carbon footprint than the current standard. But we also value biodiversity protection, as well as the reduction or elimination of toxins in manufacturing processes. Finally, we make sure that our processes are fair and equitable and that they don’t threaten local economies.

4. TECHNOLOGY

The technology has to be a fit. We really like precision fermentation with the occasional green chemistry step. We’re not crazy about algal systems or cell culture (and we have our reasons). Another consideration is technological readiness. We prefer projects that are as close to the market as possible, but realistically we onboard projects that are as early as Technology Readiness Level 3. We are fans of technologies that utilize sustainable feedstocks.

5. SCALABILITY

Scalability has two meanings for us: Firstly, in the “traditional” biotech sense, we have to have the conviction that the process can be transferred from small, lab-scale volumes to large, industrial-scale volumes. Secondly, we are looking for platforms that can scale a product portfolio. This means that we select technologies that can be easily tweaked to make similar (but different) products.

6. INTELLECTUAL PROPERTY / IP

In biotech, the value of a technology is closely linked to the strength of the associated patents. We have a workflow to assess intellectual property and are happy to in-license existing solutions. Of course, we also develop our own IP in-house. Which path to take depends on how close to our core the technology is and how long either approach would take.

7. DIFFERENTIATION IN VALUE PROPOSITION

Value lies in the eye of the customer. The value propositions of the products in our pipeline are quite diverse but are clearly differentiated from the status quo and market standard. Value can be found in following consumer trends (e.g. vegan, clean label, locally sourced, …) as well as in the production process (e.g. stable supply, drop-in solution, …). We believe that adding functionalities through sustainable processes will yield the highest value for our customers.

8. FINANCIALS

Let’s face it: Building a bio-based product is much more expensive than launching a new SaaS platform. We value sound budget plans for our in-house projects and we expect the same from partners that we co-develop with. We are not afraid of serious investments when we see a win-win.

9. REGULATION

Many people that I talk to underestimate the costs and timelines associated with launching new products. A Novel Food Application can easily take several years. We have to account for that, align the product development with the regulatory timeline and manage expectations accordingly.

10. COMPETITION

Product and customer development at different deep tech startups has taught me that every problem already has a solution (as bad as it may be). This means there is already someone or something that you are competing with when developing a new product. It is important for the success of a new product to understand who will be (negatively) impacted when our product launch is successful and how they might react.

In using these criteria, we can ensure to identify the right partners and tech to support our mission to unleash nature to grow matter with atomic precision — enabling businesses to create a world of naturally superior products for all.

Carbocycle – an example of Insempra’s tech scouting

One of the most illustrative examples of our unique tech-scouting approach is the acquisition of Carbocycle in October 2021. Carbocycle was started in 2016 by a group of scientists at Columbia University in the City of New York, as a spin-off from research funded by the Bill and Melinda Gates Foundation. Carbocycle developed an innovative technology to produce sustainable microbial lipids from upcycled organic waste streams using precision fermentation. This technology aligned 100% with Insempra’s (formerly Origin Bio) vision of tailor-made products, co-designed by nature.

The co-founders of Carbocycle — Shashwat Vajpeyi, Ph.D., Tim Zeiske, Ph.D., and Melanie Valencia, PhD(c) are now part of the Insempra team in Munich.

Combining the innovative technology of Carbocycle with Insempra’s scale-up capabilities will unlock fats and oils for the best performance for specific use cases, beginning with those focused on the fields of cosmetics and food. The developed products represent a sustainable breakthrough to replace oils and fats such as palm oil, which are associated with climate change and biodiversity loss.

This example illustrates how identifying paradigm-shifting innovation, blending expertise/knowledge and mission-driven collaboration with entrepreneurial capabilities in biotech will accelerate the generation of a better future for the planet.

Thanks for reading!

Grow your idea with us

Whether you represent a business, want to join our team or have technology with potential — Max would love to hear from you: innovation@insempra.bio

If you’d like to stay updated on Insempra’s news – sign up to our monthly newsletter here.

Munich, Germany, 21st September 2022